On January 23 and 24, a company called US Synthetic came to town and they spent their time drilling down into students heads at Creekview Elementary. Well not literally.

US Synthetic is 30-year industry veteran and a leader in the development and production of polycrystalline diamond cutters (PDCs) for oil and gas exploration. The company that employs around 830 people in Utah county has

a division called “Engineering Good” and that is the group that showed up for the activities that took place at the school that day. What could a company that makes drill bits bring to students who are barely learning how to add and divide, use basic English or are just learning about the wonderful world of science?

The answer is problem solving. For those days instead of perfecting their process to make diamond cutters the employees of US Synthetic were getting into kids heads about learning to think and solve problems that they may

face in any number of different ways. They brought along six specialists for two days to work with the students.

“At US Synthetic we have a culture of problem solving,” said Joe Weight one of the trainers for the day and who is a raw materials quality analyst at the company. “We went through a lean manufacturing transformation not long ago and we found the best way to do that is to enable our own people to solve their own problems. So instead of an old suggestion program you have with the box on the wall that people put their suggestions into we just allowed everyone to see a problem, and solve that problem. It started small and with little suggestions and has grown from just safety things like people getting their fingers burned on a daily basis and stuff like that into real money saving opportunities.”

The presentations that were given to the students included a scenario that the company faced every day. Workers were getting their fingers burned by not knowing when parts that came out of the manufacturing process for the

bits had cooled down. Weight said the firm had engineers looking at a way to measure when those could be safely handled by hand and some of the solutions ranged up to spending $10,000 on equipment to do it.

“They wanted to look at using thermal imaging cameras and all kinds of stuff,” he said. “And there were 14 of those machines that would have had to have been fitted with those measures. An employee came up with a suggestion on how to handle it for $5 per machine. It was by using thermal imaging paper.”

The video showed to the students demonstrated the problem and then showed how a simple piece of that paper could be hung above where the parts were coming out of the process and it would turn different colors, depending on

how hot the parts were. The solution not only saved pain but saved the company money in terms of avoiding those injuries.

The trainers went into classrooms that day and began by working with students on building towers out of folded card stock. First they told the students what they wanted them to do with the card stock and let groups of them in a room build towers on their own.. They gave the students a time limit and then they measured who had the tallest tower that stood up to a small weight put on top of them. Then they worked with students on what the best way to build the towers would be if they had known what they learned the first time. They talked about the structures they built being made more stout so that the project could support more weight. As the students proceeded towers in the rooms then got taller and stronger the second go around because the students could plan a little and had learned from their

mistakes. After a short video from a movie about problem solving, the instructors had them go build the structures a third time. One of the things they were taught was to test the strength of the towers at each level because, in the end, the strength of the structure is what creates the best towers. Towers got much bigger during that third construction

process.

Landon Garner, the Director of Engineering Good said that surprisingly, young students often do better than adults, even people who are highly educated and are driven, at building the towers because instead of being in a rush to build the tallest tower, they learn to test them and construct the best tower.

“Adults are always in a hurry to get them built and build the highest one,” he said as he instructed a class. “You follow instructions and test as you go.”

The concept is to use the plan, do, check and adjust (PDCA) method of construction or creation for anything that a person does.

“It is a problem solving method, very much like the scientific method,” said Weight. “It works as a very quick cycle of solving problems. Our vision at US Synthetic is to improve lives, and that includes our employees, our customers, our communities and our suppliers. Some of that is community outreach and attempting to create the worlds best problem solvers.”

The program has been presented in many schools and in other places in the world such as Nepal, Peru and Mexico.

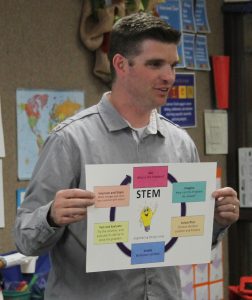

The company is heavily involved in the STEM (Science Technology Engineering and Math) program in the state and have been to two of the state STEM fairs.

Of course part of the goal of this is to get students thinking about working in industry and technology. One of the second grades students actually expressed to one of the trainers that he would like to work at the company one day and a little girl asked Weight “Do girls work at US Synthetic?”

“I said absolutely,” said Weight.

John Thomas, the Principal at Creekview said what Engineering Good was teaching the students was basically what the STEM method of doing things does with any engineering project.

“It fits right in with what we try to do with students, to get them to think and plan,” he said.